Job #2483 Huntington Sub Bridge 102 tons

Capabilities

Capabilities

Peddinghaus Ring of Fire

Peddinghaus Ring of Fire

The Ring of Fire Thermal Processor utilizes a never before seen 360º approach to plasma cutting. A single Hypertherm Plasma torch is fixed to a rotating "ring" which is capable of revolving in excess of 360º around the profile being processed. This allows the machine to process all 4 sides of a tube; process each side of a beam, angle, or channel; and mark on 4 sides of any structural member.

Mitering Capabilities

Mitering Capabilities

In addition to being able to rotate 360º around the profile being processed, the Ring of Fire from Peddinghaus is also capable of unmatched mitering. Ideal for the addition of weld prep, or compound mitering of profiles, the Ring of Fire's mitering capabilities are second to none.

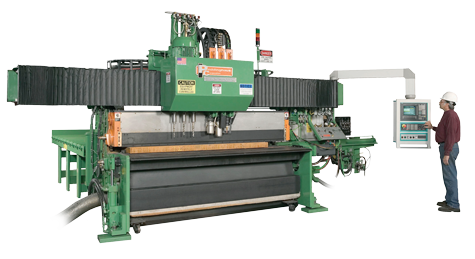

Peddinghaus FPB-500

We Reduce the need for multiple material handling routines and minimize crane usage with the FPD-500. This machine allows our operators to drill, punch, and scribe in one location, without the need to move material

01

Punching

The 120 ton triple tool punch press of the FPD allows for maximum durability and efficiency. Capable of punching holes up to 1-1/2" in diameter, and maintaining up to three available punch stations the FPD minimizes the need for tool change.

02

Tooling

Punch tooling provides an economic option for hole creation. On average up to 1,000 holes can be created using a single punch and die set before re-sharpening.

Peddinghaus FDB-2500 CNC Plate Drill With Plasma & Oxy Cutting Torches

With Peddinghaus Drill Lines, measurement happens at the machine, eliminating separate carriage or gripper feed mechanisms, allowing for total layout flexibility. Peddinghaus conveyors can be quickly expanded, split apart, transferred across from either side (datum or non datum) and modified with no sacrifice in machine accuracy or functionality.

Peddinghaus 1270 DGP Band Saw

Similar to other Peddinghaus designs, the DGP-1270 band saw utilizes a smarter design for maximum longevity of consumables, and core components. Technology that includes a unique portal frame mitering mechanism, twin column construction, rigid material clamping.

Peddinghaus BDL-1250/9B

The BDL-1250/9B Beam Drill Line is a machine designed to apply high speed steel (morse taper) drill tooling to the production of heavy structural steel members. Columns in excess of 730 lbs/ft are continually executed with ease on this one-of-a-kind system. Proven to process between 150-180 tons of structural steel per week on average (this can fluctuate based on section size and complexity of operations) the BDL-1250/9B proudly serves not only high throughput facilities, but fabricators who require the ability to process heavy wide flange beam shape and sizes. From the smallest W4 to the largest W44.

Peddinghaus ABCM-1250

- Ideal for the Automation of Common Copes: Shops that require web cutouts, flange penetrations, slotted tubes, block copes, "rat holes", "dog bones", and more find the ABCM performs each of these cuts flawlessly and at the lowest possible labor cost.

- Used for the Application of Split-T Sections: Structural split T's are no problem with the Peddinghaus ABCM-1250 coping machine.

Durma Shear

Maximum cutting length 10'-2"

Maximum cutting capacity 1/2"

Throat depth 13.8"

EMC programmable control

39" back gauge w/balls crews

60" squaring arm w/gauge stop

40" support arms with T-slot & gauge stop

“WCI provides an outstan ding service while bringing in projects on-time & on budget.”

Tyler Molesworth, P.M. Lusardi Construction

“Timely, efficient, and always willing to go above and beyond. We have not been dissatisfied on one of my projects”

Connor Moore, P.M. Harper Construction Co.